Tantalex Lithium Announces Impressive Maiden Mineral Resource Estimate for the Manono Lithium Tailings Project

| |||||||||

|  | ||||||||

Toronto, ON - TheNewswire - December 15, 2022 - Tantalex Lithium Resources Corp. (CSE:TTX) – (FSE:DW8) – (OTC:TTLXF) (“Tantalex” or the “Corporation”), is pleased to announce a Maiden Mineral Resource Estimate for its majority owned Manono Lithium Tailings project in the Democratic Republic of Congo.

KEY HIGHLIGHTS

-

5,46 million tonnes at 0,72%Li2O in the Measured and Indicated category;

-

6.63 million tonnes in total Inferred Mineral Resources at a grade of 0,49%Li2O

-

Lithium contained in spodumene and amenable for production of 6% Li2O Spodumene Concentrate (SC6)

-

Mineral Resource defined by 11 922 m of drilling in a total of 368 drillholes

-

Quick path to production: material on surface, already crushed; no strip ratio, low mining costs

MANONO TAILINGS MINERAL RESOURCE STATEMENT

The Mineral Resource was estimated using the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Best Practice Guidelines and is reported in accordance with the 2014 CIM Definition Standards, which have been incorporated by reference into National Instrument 43-101 – Standards of Disclosure for Mineral Projects (NI 43-101).

A summary of the Mineral Resource estimates per deposit as well as the total Measured, Indicated and Inferred Mineral Resources is shown in Table 1.

|

Table 1 : Manono Mineral Resources at a 0.20% Li2O cut-off grade – 13 December 2022 |

|||

|

Deposit |

Classification |

Tonnes (Mt) |

Li2O % |

|

Cc |

Inferred |

2.99 |

0.32 |

|

Ic |

Inferred |

0.67 |

0.42 |

|

Gc |

Indicated |

0.29 |

0.78 |

|

Inferred |

0.51 |

0.84 |

|

|

Gf |

Indicated |

1.39 |

0.35 |

|

Inferred |

0.13 |

0.33 |

|

|

K |

Measured |

3.77 |

0.86 |

|

Inferred |

2.33 |

0.67 |

|

|

Total |

Measured |

3.77 |

0.86 |

|

Indicated |

1.69 |

0.42 |

|

|

Measured & Indicated |

5.46 |

0.72 |

|

|

Inferred |

6.63 |

0.49 |

|

The Mineral Resource is classified into the Measured, Indicated and Inferred categories and is reported at a cut-off grade of 0.20% lithium oxide (Li2O). The cut-off grade and reasonable prospects for eventual economic extraction (RPEEE) were determined using the following assumptions:

-

Mining will be undertaken using bulldozers and loaders.

-

Mining cost: USD 2.17 per tonne of rock

-

Mining Recovery: 99%

-

Processing cost: USD 11.18 per tonne processed (RoM)

-

Revenue Royalty: 3%

-

Payability: 98.5%

-

Process Recovery LiO: 50% to 70%

-

Lithium Price: 4 000 USD/tonne (SC6 – Spodumene Concentrate)

The assessment to satisfy the criteria of RPEEE is a high-level estimate and is not an attempt to estimate Mineral Reserves.

Eric Allard, President and CEO commented: ‘’ With this Mineral Resource Estimate, Tantalex Lithium now enters a select group of near-term lithium producers. Our relatively easy and low-cost mining process gives us an incredible advantage on our speed to market compared to other lithium peers.

With SC6 lithium prices likely set to remain above $4,000 USD/t for the next 6-8 years, our focus is now to bring an initial production of 100,000 tons per annum of SC6 to market by 2025. With no offtake agreements yet entered into, our project is currently attracting important offtaker interest.’’

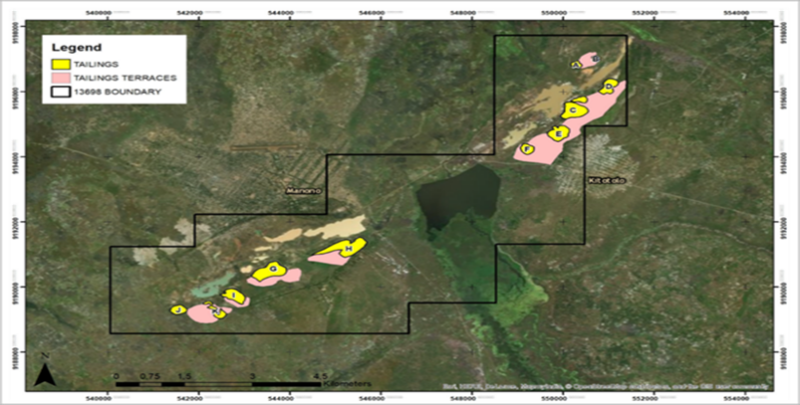

Figure 1: Licence Boundary of PER 13698 and Tailings locations

The Manono Tailings Project is composed of eleven technogenic deposits made up of the reject LCT (Lithium-Caesium-Tantalum) pegmatite material processed at the Manono-Kitotolo mine from 1919 to the mid-1980s.

Tailings from the Manono-Kitotolo mine were deposited on ground adjacent to the various open pits. The coarse tailings were deposited over several years into raised heaps that reach, in some dumps, a maximum height of 70 m above surface. The fine tailings material was deposited into flat terraces adjacent to the coarse tailings dumps.

Geology and Mineralization

The lithium mineralization is contained within technogenic deposits, consisting of eleven individual tailings dumps, of which five form part the Mineral Resource, namely Cc, Ic, Gc, Gf and K. The tailings deposits consist of a combination of processed pegmatite, laterite and clay material sourced from the historical Manono-Kitolo mine which operated from 1919 to the mid-1980s. The deposits vary in shape and size, with Cc, Ic and Gc being lobate in shape, extending 815 m by 580 m for the Cc dump, 530 m by 315 m for the Ic dump and 500 m by 320 m for the Gc dump. The height of each dump varies, with some stacked up to 78 m high above the surrounding planes. The Gf and K dumps occupy a larger footprint, with the Gf extending 760 m by 530 m, up to a maximum thickness of 33m, while the K dump has an extent of 700 m by 630 m, up to a maximum depth of 24 m. The K dump contains stacked tailings located in the northeast and eastern portions with a maximum vertical thickness of 45 m. Spodumene is the main lithium bearing mineral.

Many of the tailings deposits are composite in nature, consisting of layers of pegmatite, laterite and/or clay layers. These layers were deposited by mechanical means, including most of the deposits denoted as “fines”, for the exception of the Hf and Gf deposits. These are assumed to have formed due to the settling of fine material in standing ponds of water as evidenced by the presence of clay layers in these deposits.

Figure 2 is a photograph of the coarse material (1 mm to 5 mm gravel size) that represents the dominant tailings dump material in the Project area.

Few deposits appear to consist of a single material type, the exception to this being the K dump which is primarily composed of pegmatite. Figure 3 shows the white, pegmatite tailings and the partially vegetated cone-like feature of the stacked K dump tailings, looking south.

Figure 2: Coarse tailings size

Figure 3: K dump crescent

Sampling and Mineral Resource estimation techniques

The Mineral Resource estimate was based on geochemical analyses of samples obtained by aircore drilling undertaken by Tantalex from September 2021 to July 2022. A total of 368 drillholes have been drilled across nine tailings deposits, totaling 11 922.24 metres of drilling. The majority of the drillholes were collared on the K dump, with 2 120 metres drilled from 156 drillholes. Fifty drillholes were collared on the Gf dump, 34 on the Ic dump, 25 on the Gc dump and 20 drillholes were collared on the Ic dump.

Due to the nature and angle of repose of the stacked tailings, drilling on the slopes was not possible. Hence a majority of the material in the slopes has been included in the inferred category.

Samples were taken in one metre intervals and composited to three metres. Three sample preparation protocols were used during the drilling campaign. The first protocol was used early in the programme and involved crushing the sample down to 2 mm using a roll crusher, after which a 200 g sub-sample was obtained from a Jones Riffle splitter. This 200 g sample was then sub-sampled by the cone-and-quartering method to obtain a 100 g sample which was pulverised to better than 80% passing 75 μm. The crushing, splitting and pulverising were carried out on-site by Tantalex. The second sample preparation protocol involved the crushed 200 g sub-sample being prepared on-site and then transported to the Congolese Analytical Laboratory (COAL) in Lubumbashi where the sub-sample was pulverised to 85% passing 75 μm. For the third protocol in the latter part of the project, 400 g of sample were submitted to COAL where it was crushed to a 2 mm size fraction using a benchtop jaw crusher and then pulverised to 85% passing 75 μm.

The samples were subjected to a quality assurance and control (QAQC) programme consisting of the insertion of certified reference materials (CRMs), blanks and the inclusion of coarse duplicates. The primary laboratory assay results were confirmed by duplicate samples assayed at a second laboratory. Check samples selected by the QP were used for further confirmation of the lithium assay values and the QP is satisfied that the results are of sufficient accuracy and precision for use in Mineral Resource estimation.

Three-dimensional volumes of the tailings were constructed using drill hole data. The lithium grades were estimated into block models using ordinary kriging for the low-lying material of the K dump. The stacked material of the K dump and the Cc, Gc, Gf and Ic dumps were estimated using inverse distance weighting. Average densities were assigned to each material type.

Metallurgical Testing

A summary of the HLS results is available in 2. The HLS test produced concentrate grades of 6.5% Li2O spodumene at overall recoveries across the size range of 47% and 63% for G-dump and K-dump respectively. The testwork did not produce a SC6 product from the C-dump this requiring further investigation. These results are for all the dump material with a PSD smaller than 5mm.

The lithium recoveries increased with size fraction while the tin and tantalum required further liberation to improve recoveries.

Table 2: HLS Summary Results

|

Mineral |

Item |

Unit |

C- Dump |

G - Dump |

K - Dump |

|

Li2O |

Head Grade |

% |

0.33 |

0.61 |

1.05 |

|

Recovery |

% |

28 |

47 |

63 |

|

|

Concentrate Grade |

% |

4.9 |

6.5 |

6.5 |

|

|

Sn |

Head Grade |

ppm |

443 |

464 |

486 |

|

Recovery |

% |

34 |

41 |

24 |

|

|

Ta |

Head Grade |

ppm |

38 |

32 |

34 |

|

Recovery |

% |

43 |

20 |

10 |

Filling of Report

The NI43-101 compliant technical report (“Report”) will be filed on SEDAR within the next 45 days.

The Qualified Person for the Mineral Resource estimate is Mr. Rui Goncalves (BSc Hons, MSc (Eng.)) who is a geologist with 13 years of experience in base and precious metals exploration, mining geology and Mineral Resource estimation. He is a Senior Mineral Resource Consultant for The MSA Group (an independent consulting company), is registered with the South African Council for Natural Scientific Professions (SACNASP) and is a Member of the Geological Society of South Africa (GSSA). Mr. Goncalves has the appropriate qualification and experience to be considered a “Qualified Person” for the style and type of mineralisation and activity being undertaken as defined in National Instrument 43-101 Standards of Disclosure of Mineral Projects.

Neither Mr. Goncalves nor any associates employed in the preparation of the Mineral Resource report (“Consultants”) have any beneficial interest in Tantalex Lithium Resources Corporation. These Consultants are not insiders, associates, or affiliates of Tantalex. The results of the report are not dependent upon any prior agreements concerning the conclusions to be reached, nor are there undisclosed understandings concerning any future business dealing between Tantalex and the Consultants. The Consultants are to be paid a fee for their work in accordance with normal professional consulting practices.

Qualified person

Mr. Rui Goncalves, Pr. Sci Nat, is the Qualified Person and has reviewed and approved this press release. The information in this press release that relates to the estimate of the Mineral Resources for the Manono Tailings Project is based upon, and fairly represents, information and supporting documentation compiled by Mr. Goncalves.

About Tantalex Lithium Resources Corporation

Tantalex Lithium is an exploration and development stage mining company engaged in the acquisition, exploration, development and distribution of lithium, tin, tantalum and other high-tech mineral properties in Africa.

It is currently focused on developing its lithium assets in the prolific Manono area in the Democratic Republic of Congo; The Manono Lithium Tailings Project and the Pegmatite Corridor Exploration Program.

Cautionary Note Regarding Forward Looking Statements

The information in this news release includes certain information and statements about management's view of future events, expectations, plans and prospects that constitute forward looking statements. These statements are based upon assumptions that are subject to significant risks and uncertainties. Because of these risks and uncertainties and as a result of a variety of factors, the actual results, expectations, achievements or performance may differ materially from those anticipated and indicated by these forward looking statements. Although Tantalex believes that the expectations reflected in forward looking statements are reasonable, it can give no assurances that the expectations of any forward looking statements will prove to be correct. Except as required by law, Tantalex disclaims any intention and assumes no obligation to update or revise any forward looking statements to reflect actual results, whether as a result of new information, future events, changes in assumptions, changes in factors affecting such forward looking statements or otherwise.

The Canadian Securities Exchange (CSE) has not reviewed this news release and does not accept responsibility for its adequacy or accuracy.

For more information, please contact:

Eric Allard

President & CEO

Email: ea@tantalex.ca

Website: www.tantalexlithium.com

Tel: 1-581-996-3007

APPENDIX 1: CHECK LIST OF ASSESSMENT AND REPORTING CRITERIA

|

Drilling techniques |

Aircore drilling using a track mounted aircore/RC rig with an onboard compressor was used to collect the core samples using an 80 mm outer core bit and a 30 mm inner core diameter bit. |

|

Logging |

All drillholes were geologically logged by qualified geologists. The logging is of an appropriate standard for Mineral Resource estimation. |

|

Drill sample recovery |

The weight of the aircore sample was used as a proxy for recovery. The weight of each sample ranged from 2.5 kg to 5.0 kg. |

|

Sampling methods |

The drillhole cores were collected at a 1 m nominal length. Samples were composited to 3 m at the Tantalex sample preparation facility in Manono. The samples were bagged and sealed and despatched to the COAL laboratory in Lubumbashi. |

|

Quality of assay data and laboratory tests |

Sample preparation is divided into three protocols. The first protocol made use of the on-site pulveriser, where a 100 g sample was pulverised to better than 80% passing 75 µm. Following the breakdown of the on-site pulveriser, a 200 g sample crushed to less than 2 mm was dispatched to the COAL lab, where these were pulverised to better than 85% passing 75 µm. A breakdown of the on- site roll crusher led to the implementation of a third sampling protocol, where a 400 g sample was submitted to the COAL lab for crushing down to a 2 mm size fraction and pulverised to 85% passing 75 µm. Samples were initially assayed at ALS Ireland using a sodium peroxide fusion and Inductively Coupled Plasma Mass Spectrometry (ICP-MS). Subsequently, samples were sent to SGS South Africa for analysis by sodium peroxide fusion with a nitric acid digest and a combination of ICP-MS and Inductively coupled plasma-optical emission spectroscopy (ICP-OES). Check samples from the ALS assaying were sent to SGS South Africa for second laboratory verification. QC samples, consisting of certified reference material (CRM), blanks and coarse duplicates were routinely inserted as part of a QAQC external to the laboratories own internal QAQC process. The QAQC measured revealed the following:

|

|

Verification of sampling and assaying |

MSA observed the lithium mineralization in the sample chips and field checked a selection of drillhole collars. Check samples were taken for 16 samples from three different drillholes. |

|

Location of data points |

The drillhole collars were surveyed using differential GPS. A topographic model was constructed using 1 m contour intervals. Surveyed collar positions correlated well with the topographic model. |

|

Tonnage factors (in situ bulk densities) |

Density measurements were taken from five different tailings dumps by driving a steel cylinder into compacted tailings with the assistance of an excavator. Density was calculated as the dry weight divided by the volume of the cylinder. |

|

Data density and distribution |

A total of 368 holes were drilled across 9 tailings deposits. The K dump was drilled at 40 m by 40 m spacing, with a total of 156 holes collared. The Gf dump was drilled at 80 m by 80 m spacing, totalling 50 drillholes. The Cc, Gc and Ic dumps were drilled at variable spacing with 34, 25 and 20 holes collared in each respective deposit. |

|

Database integrity |

The Tantalex data is stored in Microsoft Excel files. MSA undertook audits on the database and NRE addressed all identified errors. The QP considers that the database is an accurate representation of the original data collected. |

|

Dimensions |

The lithium mineralisation is fully contained within the tailings deposits. The dimensions for the K deposit are 700 m by 630 m for the low-lying material, to a maximum thickness of 24 m. The stacked material on the northeast and eastern side of the K deposit attain a maximum thickness of 45 m. The Gf has an extent of 760 m by 530 m to a maximum thickness of 33 m. The Cc, Ic and Gc dumps are stacked up to a maximum thickness of 78 m, with the dimensions of Cc being 815 m by 580 m, 530 m by 315 m for the Ic dump and 500 m by 320 m for the Gc dump. |

|

Geological interpretation |

A three-dimensional geological model of the tailings volume was constructed from drillhole data and using lithology data as a guide. |

|

Domains |

Domains are based on lithology, namely pegmatite, laterite and clay. |

|

Compositing |

Samples were composited to 3 m by length weighting. |

|

Statistics and variography |

Statistical analyses of the composite grade data indicated higher lithium grades are present at the K dump which consists of pegmatite material. The Cc, Ic, Gf and Gc deposits have lower lithium grades and consist of multiple layers of pegmatite and laterite. Isotropic variograms were modelled for the K dump with ranges of 170 m in the X and Y and 8 m in the Z direction. |

|

Top or bottom cuts for grades |

Grade top caps were applied to some estimation domains. |

|

Data clustering |

Data in the K and Gf dump were drilled at regular grids of 40m and 80 m respectively. Data for the Gc, CC and Ic was drilled on variable grid, due to constraints related to the shape and elevation of these deposits. The degree of clustering is minimal, although the drilling grid in some deposits is impacted by access limitations. |

|

Block size |

A block model of 20 m N by 20 m E by 3 m RL was created with a minimum sub-cell of 2 m N by 2 m E by 0.5 m RL. |

|

Grade estimation |

Grades were estimated into parent cells using ordinary kriging for the K dump and inverse distance weighting for the Cc, Ic, Gc and Gf dumps. A minimum number of 5 and a maximum of 10 composites were required for each estimate. Elliptical searches set to the variogram ranges were used to estimate lithium for the K dump. For the other dumps that were estimated using inverse distance, the search volume considered the data spacing. The Gf deposit was estimated using a search volume 100 mX by 100 mY by 3 mZ and Cc, Ic and Gc were estimated using a search volume 60 mX by 60 mY by 6 mZ. Where insufficient samples were available for estimation in the first search pass, the search was increased by a factor of 1.5. A third pass using a search 110 times the first search was used to ensure the entire model was estimated. Density was assigned to the block model based on the average value per material type. |

|

Resource Classification |

The classification was based on the degree of geological uncertainty of the material constituting each deposit, grade continuity and variability and the frequency of the drilling data informing the estimates. Mineral Resources were classified as Measured where drillhole spacing is 40 m apart and where sufficient grade continuity is observed. This corresponds to the low-lying material of the K dump. Areas informed by a nominal grid spaced 40 m to 80 m apart and extrapolated 40 m from the nearest drillhole were classified as Indicated Mineral Resources, corresponding to the Gf dump and densely drilled areas of the Gc dump. Inferred Mineral Resources correspond to those areas where confidence in the estimates is low, namely the Cc, Ic and large areas of the Gc dump. |

|

Metallurgical factors or assumptions |

Initial metallurgical testwork was undertaken in 2022 with the purpose of characterising the material of each dump in terms of particle size distribution (PSD) and grade and determining the mineralogy of the tailings material. Beneficiation testwork using heavy liquid separation produced a Li2O concentrate grade of 4.9% for the C dump and 6.5% for the G and K dumps. |

|

Audits, reviews and site inspection |

The Manono Tailings was visited by Rui Goncalves, who is a Senior Mineral Resource Consultant with MSA and the Qualified Person for this Mineral Resource Estimate, from 29 to 30 April 2022. The occurrences and setting of the lithium mineralisation were observed in the field as well as the drillhole samples completed at the time. The QP was satisfied that the procedures and protocols are appropriate for the style of mineralisation at the Manono tailings project. No external reviews of the Mineral Resource Estimate have been completed |