Archive

Test Battery Update

| |||||||||

April 29, 2021 - TheNewswire - Vancouver, B.C. - Green Battery Minerals Inc. (TSXV:GEM) (FSE:BK2P) (WKN:A2QENP) (OTCQB:GBMIF) (“Green Battery” or the “Company”) is pleased to provide an update on the building of their test battery, which is being made from graphite from their road accessible Berkwood Graphite Project, northern Quebec.

GREEN BATTERY MINERALS’ mission and strategy is to become one of North America’s largest producers of clean, environmentally friendly high-quality anode materials to be used in batteries for electric vehicles and renewable energy storage.

The process of building a test battery from our graphite is underway.

Tom Yingling President and CEO states, “We are pleased to announce the large-scale purification process so far is going as planned. Approximately two years ago we tested small samples and I am pleased to confirm that we have recently reconfirmed success in large scale tonnage testing initially. So far, the results have repeated themselves and we are very pleased to see such high-grade graphite that is easily separated and purified. Proving back up and repeatability of these processes is essential in attracting Lithium Ion battery manufacturers. One of the next steps will be purifying the Graphite to 99.95% purity, also previously done, and creating the anode to be tested in Lithium Ion batteries.”

Development of our anode material for a Test Battery - This is under way. The process starts by taking material from the ground, which contains graphite and host rock, and then purifying it with the intentions on testing our graphite as the anode in a finished battery. Several of these steps have already been confirmed two years ago and Green Battery has contracted another independent laboratory to process several thousand tons of our Graphitic material on a much larger scale than the precious laboratory. This will provide a much larger purified sample that we will send for further purification to 99.95% which will allow us to send samples to battery manufactures. This second independent laboratory will also produce a second back up of test results. This back up results should assist in reaching out to Lithium Ion battery manufactures. The previous test results and current repeat test results are as follows:

-

-

a. Extracting representative rock samples from the site: (Completed though our drill programs, channel sampling and rock sampling)

-

b. Crushing the rock samples: Small sample completed two years ago and recently reconfirmed successfully in large scale tonnage.

-

c. Floating the graphite in a high-grade concentrate from the host rock: Small sample completed two years ago and recently reconfirmed successfully in large scale tonnage.

-

d. Purifying to 99.95% using the clean alkaline process: Small sample completed two years ago and preparing large scale tonnage to be tested.

-

e. Spherization for battery use: (Still to be performed)

-

f. Coating of the spheres: (Still to be performed

-

g. Making an anode: (Still to be performed)

-

h. Testing our anode against other standard anodes: (Still to be performed)

-

The process of purifying graphite starts with the crushing of the host rock that contains the graphite. The graphite flakes are then separated using flotation.

Base Metallurgical Laboratories Ltd., States:

To accomplish the concentrate generation, the process will be simulated in large batch or pilot equipment. Flotation processing can include Hydrofloat or conventional flotation. Gravity concentration will be performed on a Diester table.

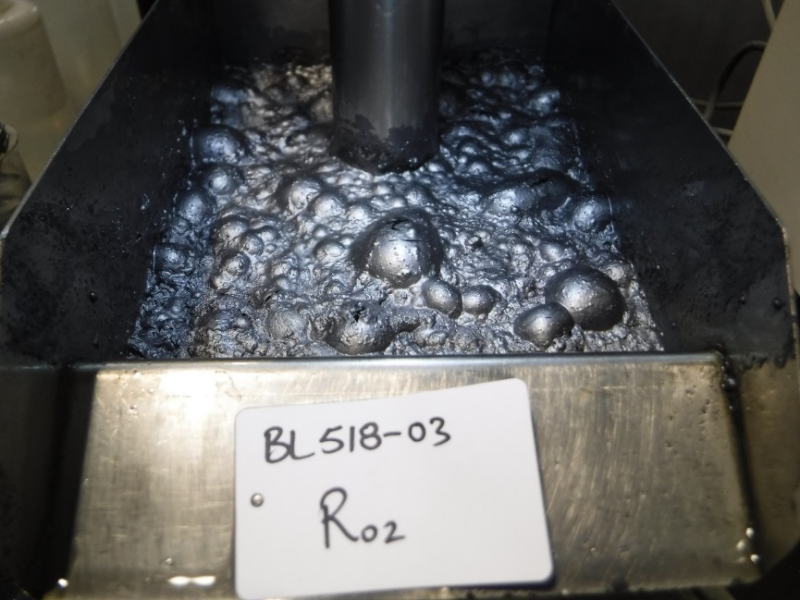

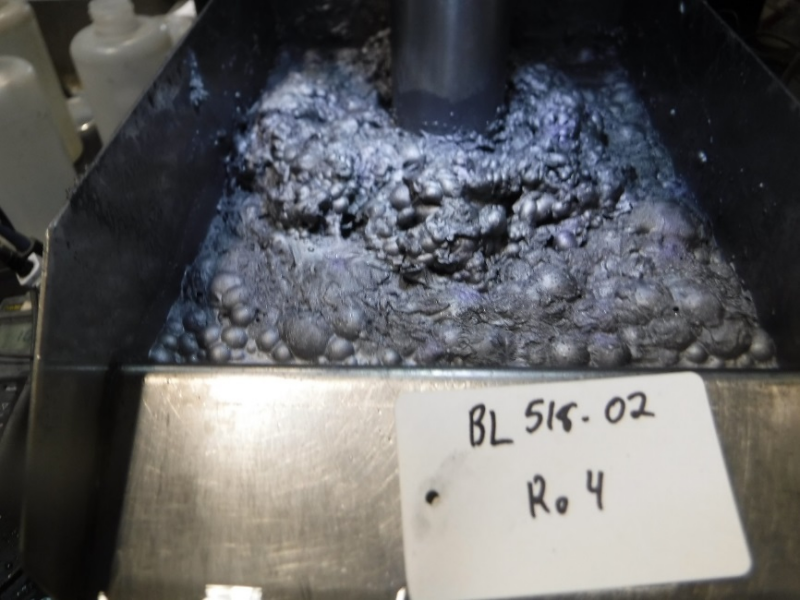

Below is a visual of the process:

CORE FROM SAMPLING AND DRILL PROGRAMS:

The graphite bearing rock sample from our drill core and surface sampling were shipped to Base Metallurgical Laboratories Ltd. These were then crushed, and the samples homogenized in four main composites.

CRUSHING PROCESS:

Samples were ground in a rod mill to the various grind sizes and tested in conventional rougher flotation tests. Cleaning and polishing tests are to follow.

Graphite before and after crushing.

FLOTATION SEPARATION:

Graphite floats, it is put into flotation baths and a number of different process are used to have the graphite float to the top where it can then be removed.

Qualified Person: Mr. Dave Kelsch, P.Geo. is a Qualified Person (“QP”) as defined by National Instrument 43-101 guidelines, and he has reviewed and approved the technical content of this news release.

About the Company: Green Battery Minerals is managed by a team with over 150 years collectively with a proven track record of not just finding numerous mines but building and operating them too. The Green Battery Mineral management team’s most recent success is the discovery of the Berkwood Graphite resource in Northern Quebec. Green Battery Mineral owns this asset 100 percent and the Company’s shareholders will benefit from this asset as the demand for Graphite for electric vehicles increases significantly.

On Behalf of the Board of Directors

Green Battery Minerals lnc.

‘Thomas Yingling’

President, CEO & Director

FOR MORE INFORMATION, PLEASE CONTACT:

Investor Relations:

or 1-604-343-7740

info@greenbatteryminerals.com www.greenbatteryminerals.com

Disclaimer for Forward-Looking Information:

Certain statements in this release are forward-looking statements, which reflect the expectations of management. Forward-looking statements consist of statements that are not purely historical, including any statements regarding beliefs, plans, expectations or intentions regarding the future. Such statements are subject to risks and uncertainties that may cause actual results, performance or developments to differ materially from those contained in the statements. No assurance can be given that any of the events anticipated by the forward-looking statements will occur or, if they do occur, what benefits the Company will obtain from them. These forward-looking statements reflect management’s current views and are based on certain expectations, estimates and assumptions, which may prove to be incorrect.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.