Archive

Tantalex Lithium Achieves 6+% Li2O Spodumene Concentrate Grade in HLS Metallurgical Test Work on the K-dump for the Manono Tailings Reclamation Project, DRC

| |||||||||

|  | ||||||||

-

Heavy Liquid Separation (“HLS”) tests on a 2 ton bulk samples taken from the K-dump produced a 6+% LiO spodumene concentrate at four different size classifications.

-

HLS tests produced a 6.5% Li2O spodumene concentrate at overall lithium recoveries exceeding 60%.

-

Fe content of +- 1.3% in final spodumene concentrate to be reduced further with magnetic separation in Phase 2 testworks.

-

HLS testing is the industry standard lab bench scale testing to establish if physical metallurgy will be sufficient to beneficiate mineral deposits into sellable concentrates.

-

-

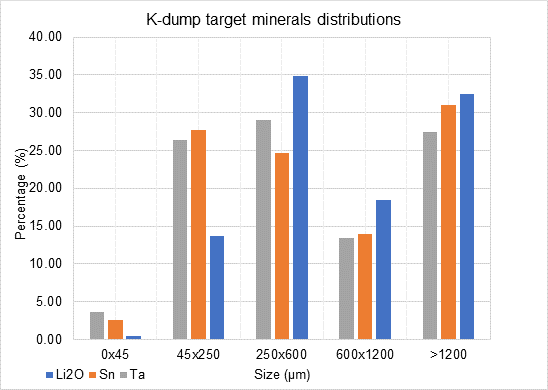

In the K- dump, LiO, Sn and Ta are evenly distributed across the different size fraction from -5mm to +45 µm. Lithium recoveries increased with size fraction while tin and tantalum had improved recoveries in the finer fractions which indicated that the tin and tantalum required further liberation to improve recoveries.

-

Upstream classification, Dense Media Separation (“DMS”) and gravity concentration technologies will be evaluated during the Phase 2 testwork program to design the optimal plant for lithium, tin, and tantalum extraction.

Toronto, Ontario – TheNewswire - September 13, 2022 – Tantalex Lithium Resources Corp. (CSE:TTX) – (FSE:DW8) – (OTC:TTLXF) (“Tantalex” or the “Corporation”), is pleased to announce the results of the metallurgical testwork on a 331 kg composite bulk sample (sub sample of the approx. 2 tonne sample taken from drillholes locations MDC047, MDC056 and MDC 064 ) collected from the K-dump at the Manono Reclamation Project located in the Tanganyika province of the Democratic Republic of the Congo (“DRC”). Mineralogical analysis indicated that nearly all the lithium is contained in Spodumene. It was further determined that Cassiterite is the only tin bearing mineral and in the case of tantalum the overwhelming majority occurs as Tantalite with low concentrations of Tapiolite.

The HLS tests have resulted in 6+% Li2O spodumene concentrates at high lithium recoveries exceeding 60% and an iron content of approximately 1.3% Fe2O3 without conducting any magnetic separation on the concentrate produced. Although HLS results are only an indication of a DMS circuit’s performance in operation, the results indicate that DMS will be applicable to the Project’s flowsheet as a primary driver for lithium recovery in the coarse fraction. Additional conventional technologies will be tested to establish the optimal beneficiation of the -0.5mm fraction.

A summary of HLS test work results for the K-dump can be seen in the table below. It is important to note that the current test campaign only focused on primary upgrades of tin and tantalum.

|

Mineral |

Item |

Unit |

K-Dump |

|

Li2O |

Head Grade |

% |

1.05 |

|

Recovery |

% |

63 |

|

|

Concentrate Grade |

% |

6.5 |

|

|

Sn |

Head Grade |

ppm |

480 |

|

Recovery |

% |

24 |

|

|

Concentrate Grade |

% |

26 |

A primary reason for the strong HLS results is the coarse-grained nature of the spodumene at K-dump which allows for strong liberation of the spodumene with no crushing required as the in-situ material is 99% -5 mm. What this means for the company is that the coarse fraction spodumene can be processed using the most conventional mineral processing technique in the industry without any additional crushing/grinding required. The cut density can also be lowered from 2.95 t/m3 that were utilised in the testwork to improve recoveries while maintaining SC6 grade.

In the K dump, Li2O, Sn and Ta are evenly distributed across the different size fractions from 45µm to >1.2mm as seen on Figure 1. A low amount of Li2O, Sn and Ta reported to the ultra-fine (-45µm)

Figure 1: Li2O, Sn and Ta distribution in the -5mm material K-Dump

The HLS testwork indicates that there is potential to opt for a phased approach in constructing the plant by firstly beneficiating the coarse fraction in a robust cost-effective way while expanding the process facility at a latter stage to recover the fine valuable material.

Hannes Miller, Company COO, comments: “The results from this initial testwork is encouraging given it is dump material. The asset has very little mining cost associated with it and producing a marketable product with a robust well-known process is strongly preferred to a flotation only operation. Dense Media Separation (DMS) is a less complicated process to operate, more cost effective, and may be commissioned over a significantly shorter timeframe. I look forward to the results of the planned phase 2 metallurgical testwork”.

The metallurgical test program was completed by CoreMet Mineral Processing in South Africa. The program included head characterisation and HLS test work to develop appropriate beneficiation methods. The full report will be released in the near future which includes the testwork results for C-dump and G-dump.

The phase II testwork will include a DMS, gravity, upstream classification, and flotation test run utilising the remaining bulk sample. The primary objective is to confirm the HLS results as well as to refine the mineral processing flowsheet for the project. The coarse fraction is expected to be processed through a DMS circuit with the DMS middlings and fines fraction (-0.5mm) processed through a gravity circuit to recover the tin and tantalum bearing minerals while the tailings will undergo flotation testwork to establish the full potential that can be achieved on the K-dump. Further work will include magnetic separation and upstream classification to remove impurities in the spodumene concentrate.

Qualified Person

The scientific and technical content of this news release has been reviewed and approved by Mr. Gary Pearse MSc, P. Eng, who is a “Qualified Person” as defined by National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”).

About Tantalex Lithium Resources Corporation

Tantalex is an exploration and development stage mining company engaged in the acquisition, exploration, development and distribution of lithium, tin, tantalum and other high-tech mineral properties in Africa. The Corporation is listed on the Canadian Stock Exchange (symbol: TTX) Frankfurt Stock Exchange (symbol: DW8) and OTCQB Venture Market (symbol TTLXF).

Cautionary Note Regarding Forward Looking Statements

The information in this news release includes certain information and statements about management's view of future events, expectations, plans and prospects that constitute forward looking statements. These statements are based upon assumptions that are subject to significant risks and uncertainties. Because of these risks and uncertainties and as a result of a variety of factors, the actual results, expectations, achievements or performance may differ materially from those anticipated and indicated by these forward looking statements. Although Tantalex believes that the expectations reflected in forward looking statements are reasonable, it can give no assurances that the expectations of any forward looking statements will prove to be correct. Except as required by law, Tantalex disclaims any intention and assumes no obligation to update or revise any forward looking statements to reflect actual results, whether as a result of new information, future events, changes in assumptions, changes in factors affecting such forward looking statements or otherwise.

The Canadian Securities Exchange (CSE) has not reviewed this news release and does not accept responsibility for its adequacy or accuracy.

For more information, please contact:

Eric Allard

President & CEO

Email: ea@tantalex.ca

Website: https://tantalexlithium.com/

Tel: 1-581-996-3007